Expert Cane Sugar Processing Chemicals: Superior Results

Expert Cane Sugar Processing Chemicals: Superior Results

Blog Article

Maximizar Rendimientos Y Minimizar Costos: Estrategias Avanzadas Para La Optimización Química Del Procesamiento De Azúcar De Caña

In the world of walking cane sugar handling, the search of maximizing yields while simultaneously lessening expenses stands as a powerful difficulty that requires a strategic blend of innovative chemical optimization strategies. Among this complex internet of approaches exists the pledge of unlocking untapped potential and revolutionizing the really significance of sugar production.

Chemical Analysis for Performance

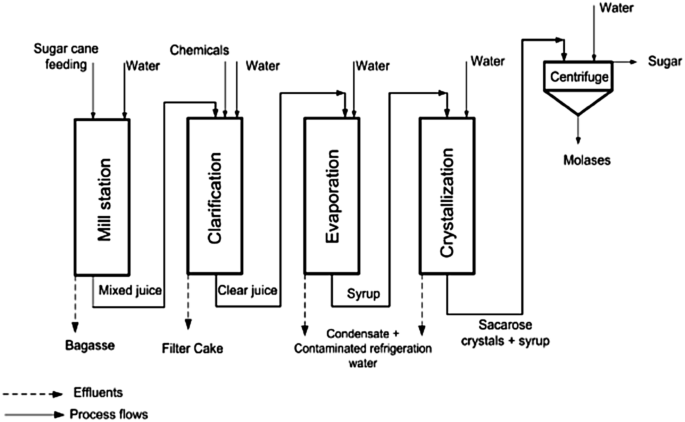

Chemical evaluation plays a crucial duty in improving the efficiency of sugar cane handling by supplying vital insights right into the structure and homes of the raw materials. By carrying out thorough chemical evaluations on sugar cane samples, processors can determine the specific focus of sucrose, sugar, fructose, and other parts existing in the raw product. This info is essential for optimizing the numerous stages of the sugar walking cane processing chain, from milling to crystallization.

In addition, chemical analysis allows processors to recognize pollutants such as natural acids, proteins, and minerals that can influence the quality and return of the final sugar product. By measuring these impurities, cpus can implement targeted methods to remove or alleviate their results, eventually boosting the overall effectiveness of the handling plant.

Furthermore, chemical evaluation facilitates the tracking of procedure parameters such as pH, temperature, and thickness, permitting processors to make real-time adjustments to make sure optimum conditions for sugar extraction and formation. On the whole, a thorough understanding of the chemical composition of sugar walking stick is crucial for maximizing yields, lessening prices, and maintaining high product quality in the sugar production market.

Enzyme Use for Increased Returns

With a tactical method to enzyme application, sugar cane processors can significantly improve their returns while keeping functional effectiveness in the production process. Enzymes play a critical role in sugar walking cane processing by breaking down intricate carbs into easier sugars, hence increasing the overall sugar extraction effectiveness. By including specific enzymes tailored to target the different elements of sugar walking cane, such as cellulose and hemicellulose, processors can boost the release of sugars throughout extraction.

Enzyme application provides the advantage of making the most of sugar yields from the raw material while lessening the power and sources needed for handling. Via mindful selection and application of enzymes, sugar cane cpus can maximize their procedures to accomplish higher yields and profitability.

Ph Control for Optimum Handling

Enzyme usage for boosted yields in sugar cane handling lays the foundation for attending to the important element of pH control for optimal handling performance. Maintaining the appropriate pH degree throughout different stages of sugar walking cane processing is vital for maximizing returns and reducing prices. pH control is specifically critical during the removal and information processes. In the removal phase, preserving the correct pH aids in achieving reliable sucrose extraction from the walking cane. Regulating the pH throughout clarification aids in the precipitation of impurities and non-sucrose parts, causing a purer final item. Furthermore, pH affects the activity of enzymes associated with the break down of macromolecules, influencing the overall effectiveness of the procedure. By thoroughly monitoring and changing the pH degrees at different processing actions, sugar walking stick cpus can improve sugar recuperation rates, minimize chemical use, and optimize the general manufacturing procedure. Efficient pH control not just boosts the quality of the final item yet go to this web-site also contributes to sustainable and his comment is here cost-effective sugar walking stick processing operations.

Advanced Filtration Techniques

Executing advanced purification techniques in sugar cane processing improves the performance and purity of the last product through improved separation methods. By integrating advanced purification modern technologies, such as membrane filtration and activated carbon purification, sugar walking cane processing plants can accomplish greater degrees of sugar healing and enhanced high quality control.

Turned on carbon filtering is one more innovative technique that aids in the removal of colorants, off-flavors, and residual contaminations from sugar cane products. By utilizing activated carbon's adsorption properties, this filtration method boosts the clarity and preference of the sugar, fulfilling the high criteria demanded by customers and industry guidelines.

Energy-Efficient Purification Approaches

Energy-efficient distillation techniques are necessary for maximizing the sugar walking stick handling market's power consumption while preserving top notch item requirements. Typical distillation procedures can be energy-intensive, bring about greater manufacturing prices and environmental impacts (Cane Sugar Processing Chemicals). Executing energy-efficient purification methods, such as vacuum distillation or molecular purification, can considerably minimize energy requirements while enhancing total process effectiveness

Vacuum purification involves decreasing the pressure within the purification system, which reduces the boiling factor of the fluid mix being processed. This reduction in boiling factor decreases link the energy required for vaporization, leading to energy savings compared to traditional purification approaches.

On the various other hand, molecular purification utilizes short path distillation techniques under high vacuum cleaner problems to separate compounds based on their molecular weight. This method is specifically effective for heat-sensitive materials, as it operates at reduced temperature levels, minimizing energy consumption and maintaining item quality.

Conclusion

Report this page